Meeting

• Confirmation of custom request

• Confirmation of use

• Confirmation of on-site line

• Confirmation of the schedule

• Product number, size, color, etc.

• Lot used

• Receive samples of actual product

"We design our own molds according to the customer's request.”

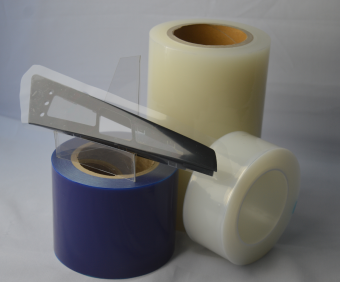

Die-cut processing is Daikyo's expertise. We offer designs and solutions that will suit your requirements and applications.

| 1. | We can provide in-depth proposals for product planning, creating design and layout, development and processing. |

| 2. | We can provide designs and layout that will not only improve the quality of the product but will also improve the processing lead time and provide a more efficent cost. |

| 3. | We are capable of gathering and analyzing collection of valuable data through our wide range of testing equipments. |

| 4. | Our flexibilty in catering our customer needs by the use of our global organizational framework. |

| 5. | Our enthusiasm to develop and create new adhesive products. |

DIPI's salespeople are great partners for our customers. Our company's original brand is named “IVY”. Just as the ivy plant can find its way into small spaces, we strive to be great partners for our customers by working together to fulfill ever-changing customer needs, no matter how small or niche, for everything from materials, adhesives, shapes, and packaging, to worksite equipment, and everything else required to complete a product.

| • | Creating the final blueprint for designing, developing, testing and, mass production of the product. |