CONTACT US IF YOU NEED PRINTING

If you have trouble with the keywords "adhesion" and "processing", please feel fee to contact us!

Processing

| ◆ | We can provide integrated production for everything from adhesive application to punching, and inspections. |

| ◆ | Feel free to contact us for consultations on orders with productions start speeds other companies refused. |

| ◆ | We have a long proven track record of projects from prototyping at production development stages to mass production. |

| ◆ | We can also handle order for just inspections and assembly. |

| ◆ | In addition to processing, we can also offer proposals for shaping and delivery specifications. |

- Slitting

- Laminating

- Sheet Cutting

- Die-cutting / Pressing

Slitting

| ◆ | This process or method uses a circular blade to slice or slit the log roll into the desired width size according to what is requested or required by the customer. |

| ◆ | The process is done by thrusting the circular blade into the rotating material so as the blade also rotates thus slitting or cutting the said material. |

|

CAPACITY: 600 mm (MAX DIMENSION)

◆ Machine for processing sheet type materials.

◆ This machine can convert large sheet of materials into smaller sizes. |

|

CAPACITY: 1,100 mm (MAX DIMENSION)

◆ Machine for processing log roll type materials. ◆ This machine can convert log roll materials into smaller width sizes. EXAMPLE: 1,200mm x 100m log roll can be slitted into 100mm x 100m roll. ◆ It can slit up to 10mm width. |

|

CAPACITY: 1,600 mm (MAX DIMENSION)

◆ Machine for processing log roll type materials. ◆ This machine can convert log roll materials into smaller width sizes. EXAMPLE: 1,200mm x 100m log roll can be slitted into 100mm x 100m roll. ◆ It can slit up to 10mm width. |

|

CAPACITY: 1,000 mm (MAX DIMENSION)

◆ Machine for processing jumbo roll materials. ◆ This machine can convert jumbo roll materials into smaller log roll sizes. EXAMPLE: 1,000mm x 500m log roll can be rewinded into 1000mm x 100m roll. ◆ This machine can also slit the log roll into smaller width during rewinding process. |

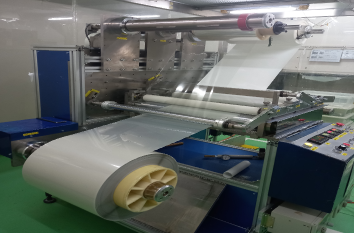

Laminating

| ◆ | The manner of binding or adhering an adhesive material with different substrate materials such as paper liner, film liner, and stiffeners during this process or method depends on what laminated material is needed based on the requirement of the succeeding operation. |

|

CAPACITY: 500 mm (MAX DIMENSION)

◆ This machine can process lamination of different types of adhesives, paper and film separator. ◆ It can also process dry - edging and edge trimming. |

|

CAPACITY: 230 mm (MAX DIMENSION)

◆ This machine can process lamination of different types of adhesives, paper and film separator. ◆ It can also process dry - edging and edge trimming. |

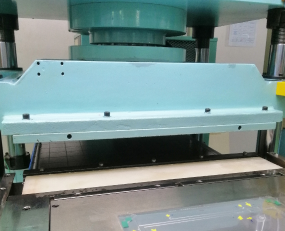

Sheet Cutting

| ◆ | In this process, the roll material is unwinded and processed in sheets through shear cutting. The material passes through the shear blade cutting it into the desired length of the sheet. |

|

CAPACITY: 520 mm (MAX DIMENSION)

◆ This machine can cut large roll type materials into sheet form depending on the desired size of the customer. |

|

CAPACITY: 100 mm (MAX DIMENSION)

◆ This machine can cut small roll type materials into smaller sheets. |

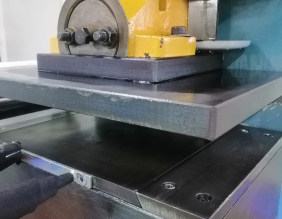

Die-cutting / Pressing

| ◆ | Our company’s main strength is processing adhesive tapes and other materials into the shapes desired by customers. |

| ◆ | We devote ourselves to further improve our customer's product quality, in collaboration with die and equipment manufacturers. |

| ◆ | Based on the punching expertise and analysis of accumulated data that only our company can offer with our proven track record of successful fulfillment of orders for processed products for a wide range of industries. |

| ◆ | We can also accommodate short turn-around times for prototypes, etc., through the use of cutting machines, laser machines, and more. |

|

CAPACITY: 110 mm (MAX DIMENSION)

PROCESS: This machine can process rotary die cutting, dry - edging, edge trimming and lamination. |

|

CAPACITY: 520 mm x 460 mm (MAX DIMENSION)

CATEGORIES OF MATERIALS: Sheet material, such as: PET, PC, PVC, copper foil, aluminum foil, rubber, foam, and so on. KEY FEATURES: The flatness of ± 0.01mm, high stability, large table, long mold life, mechanical actuation and high security. FPC products rushed processing of double-sided tape - type processing. Suitable for mold: etching knife, plastic knife, wooden knife. |

|

CAPACITY: 383 mm x 320 mm (MAX DIMENSION)

CATEGORIES OF MATERIALS: sheet material, such as: PET, PC, PVC, copper foil, aluminum foil, rubber, foam, and so on. KEY FEATURES: The flatness of ± 0.01mm, high stability, large table, long mold life, mechanical actuation and high security. FPC products rushed processing of double-sided tape - type processing. Suitable for mold: etching knife, plastic knife, wooden knife. |

|

CAPACITY: 290 mm x 250 mm (MAX DIMENSION)

DRIVING SPEED: 1,800 - 12,000 times/hour ◆ This machine can process pressing/die cut items in roll finish, lamination and, sheet cutting. |

|

CAPACITY: 270 mm x 270 mm (MAX DIMENSION)

DRIVING SPEED: 1,800 - 12,000 times/hour ◆ This press achieves high-speed machining with a thrust of 50kN and 300spm by maintaning stable punching accuracy and lowering the center of gravity of the power section. ◆ It can process die cutting of small to medium sized sheets of material. Compatible with thompson die and pinnacle die |